Pulley (Drum)

PULLEY

Pulley (Drum)

A pulley (or drum) is one of the key components in conveyor systems — responsible for transmitting power, guiding, tensioning, and changing the direction of the belt. Because of its critical role in enabling continuous, uninterrupted operation, a pulley must be carefully designed and selected. The pulley acts as an intermediary between the motor and the belt, and through its rotation, causes the belt to move. Depending on the installation point in the system, a pulley may transmit driving force, guide the belt along the correct path, or provide the necessary tension to the belt.

Technical Specifications of Pulley

Camel Sanat Engineering Company — leveraging its technical knowledge and practical experience — specializes in the design and manufacture of material-handling components, especially for conveyor systems. This company produces drums (pulleys), rollers, and related frames following international standards, while maintaining a fully equipped laboratory compliant with ISO 17025. By doing so, it meets the needs of domestic industries and also serves international markets.

Efficient power transmission to the belt and optimized conveyor performance.

Extended belt life and related components by preventing belt slippage and wear.

Reduced energy consumption through minimized friction and improved system efficiency.

Enhanced safety by reducing the risk of sudden pulley failure.

Types of Pulleys

Different types of pulleys are used in conveyors — each with a specific role, from driving and tensioning to guiding belt path. Proper design and selection of each type have a direct impact on system performance and durability.

Bend Pulley

Bend Pulley

Used where the belt’s direction needs to be changed. Typically used at points where the conveyor path curves.

Tail Pulley

Tail Pulley

Located at the end of the conveyor; serves as a support and guides the belt return. It helps precisely guide the returning belt.

Snub Pulley

Snub Pulley

Used to increase the wrap angle of the belt on the drive pulley, enhancing friction and improving power transfer from the drive pulley to the belt.

Take up /Tension Pulley

Take-Up / Tension Pulley

Used to maintain uniform belt tension and align the belt’s carrying path with the return path. Typically installed in systems with a mechanism (spring or weight) to automatically adjust tension and prevent the belt from slackening or over-stretching.

Drive Pulley

Drive Pulley

Often located at the start of the conveyor belt movement; it is directly connected to the motor or gearbox. This pulley transmits the motor’s rotational force to the belt. Usually larger in diameter than other pulleys and often covered with a special lagging to increase friction.

Important Considerations in Selecting or Designing a Pulley

The pulley must be selected according to the type of conveyed material and environmental conditions (temperature, humidity, dust, etc.).

The diameter and shell thickness of the pulley must be designed based on the applied load and working conditions.

In corrosive or humid environments, the pulley should have corrosion-resistant coatings (e.g. galvanization or stainless steel).

The design should allow easy access to bearings and hubs for maintenance or replacement.

Use of high-quality raw materials and tight manufacturing tolerances to ensure stable and safe operation.

Components of a Pulley

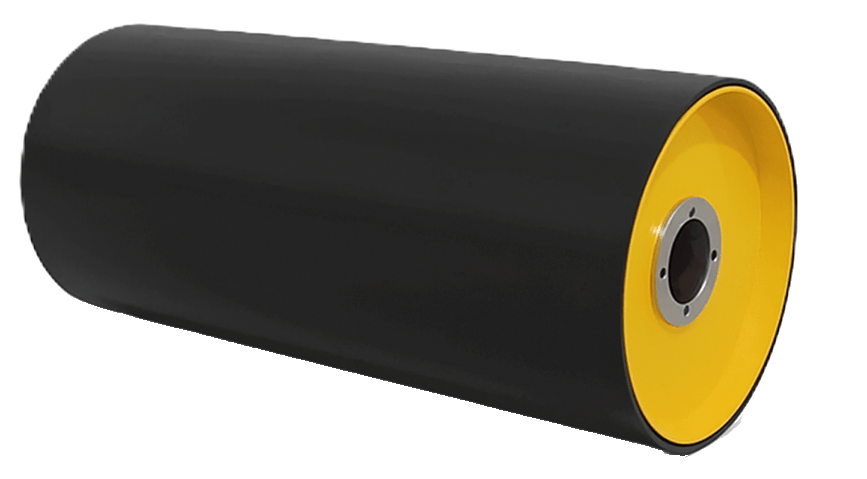

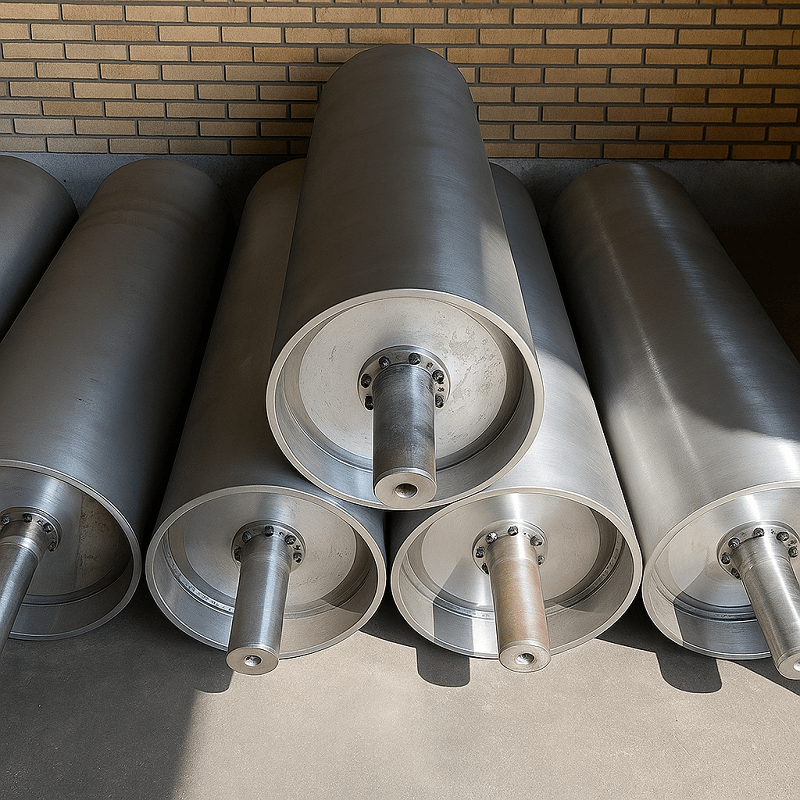

- Shell (Body): A cylindrical body made of sturdy steel, designed to withstand pressure, impact, and abrasion.

- Hubs: Mounted at both ends of the shell, they house the shaft — providing an effective connection for power transfer and allowing easy replacement.

- Shaft: A steel shaft running through the center of the pulley, connected to the motor or gearbox, transmitting torque.

- Bearings: Provide smooth rotation of the drum and help reduce friction during operation.

- Lagging (Coating / Covering): The drum’s outer surface is often covered with a layer of rubber or polyurethane to increase friction and prevent belt slippage. This lagging helps grip the belt and extends its service life.